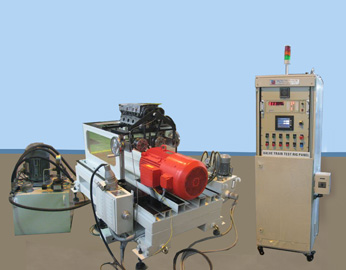

Valve Train Test Rig

The Valvetrain Test Rig is designed to carry out durability testing of engine valve train components.

Testing parameters:

- Endurance test for engine valve train components.

- Component development validation.

- Measurement of critical temperature, pressure & force measurement.

- Customized electronic control with Plc + Hmi based system.